How it Works

REEL

- The operator punches in the list of sets he wants to produce and the necessary parameters (diameter, length, core diameter, bad paper, fill-up, top, etc.).

- He relies on the current floor inventory to reduce overruns and underruns.

- Our system uses special algorithms to calculate the optimal turn-up size by accounting for parameters such as compression, grade history and spool diameter.

- We automatically trigger the turn-up.

AUTOMATED PRODUCTION

TRACKING AND OPTIMIZATION

- All jumbos are automatically identified and tracked with RF ID tags.

- All production data is indexed in great detail by RF ID tags and jumbo roll numbers.

- Our system will automatically identify all paper slabbed or patched in a roll without operator intervention.

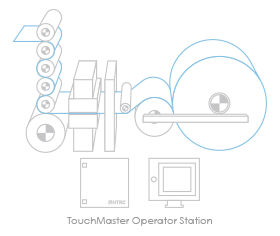

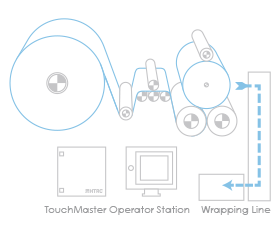

WINDERS

- The operator uses information provided by the JumboMaster® to manage automatic stops, paper slabs and patches.

- Our Roll Set Estimator Tool helps the operator make the right decisions about jumbo rolls at the winder.

- Our system will initiate a quick and precise stop or slow down when required.

- Save time with our fast and accurate Automatic Stop on Defects (ADTS).

LINKS

- QCS

- Defect Detectors

- Wrapping Line

- PI

- Drives (Analog or Digital)

- Mill-Wide

- SAP

- Lab Systems

SERVER

- The central server collates and combines all dry-end production information.

Includes all drives (analog or digital), DCS, QCS, defect detectors, mill-wide, SAP, lab systems and wrapping line.

- Get easy access to all dry-end data from anywhere in the mill.

VISUALIZATION STATIONS